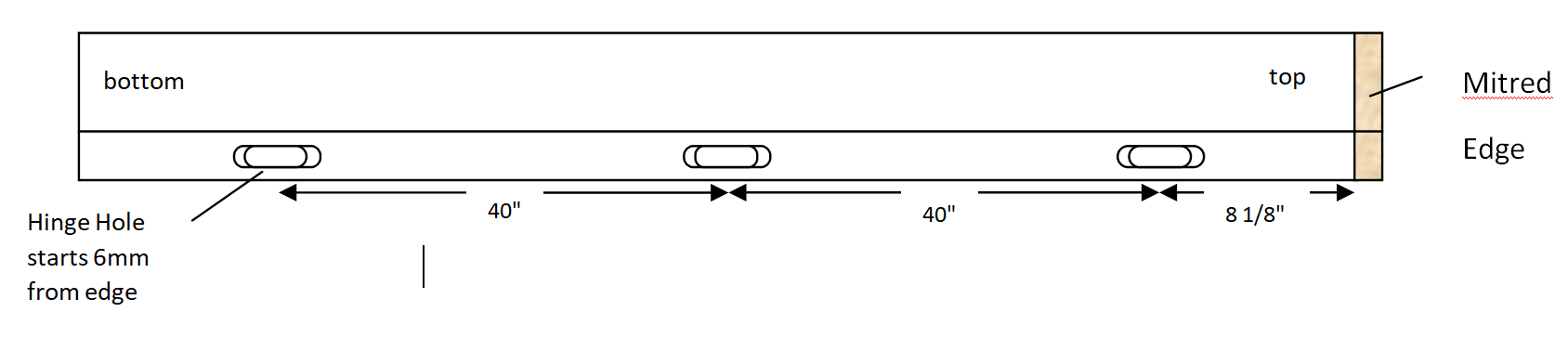

A Guide to making Frameless Interior Doors YourselfFrameless Doors do not have to be bought from a door supplier - you can make them yourself. That way you have more control and save a fair amount of you money. Now, DIY projects are not for everyone but some people might like the challenge and professional contractors and construction companies already have a lot of know-how and the right tools for the job as well. I have outlined the steps involved from sourcing material to building your frameless interior doors and finally to the installation and painting of the final product. Components of a Frameless Door 1) Door Frame also know as a Concealed Door Frame because it will not be visible after it is installed. 2) Flush Door Panel (or door slab) 3) Hidden Hinges (3D adjustable) 4) Magnetic Strike Plate 5) Door Handle - a regular handle or know or possibly an "Invisible" handle Step 1: Sourcing the Right Materials for your Doors Door Frames: For our frame we will use Wood - primed Pine or Fir to be exact. We could use Aluminum frames which are the most common type of frame material used today but working with Aluminum extrusion is more difficult and costly than using primed wooden door jambs. And more people like the average handyman have had experience with wood working - cutting it, sanding it, trimming it, painting it, and so on. The best place to look for frame raw material is your local hardware store. Any larger chain like Home Depot or Lowe's will carry or can order Primed Single Rabbet Interior Door Jambs for you. They come in 4 9/16" or 6 9/16" widths and their lengths are usually 100". That means you can build doors that are up 96" tall. In most instances that will be tall enough (even if you have 10' ceilings). You will need 2 1/2 lengths of these door jambs to build 1 Single Frameless Door. These door jambs are either made for 1 3/8" thick door panels or 1 3/4" door panels. The 1 3/4" thickness choice is the correct one for Frameless Interior Doors. So, if your walls are build with 2x4s and you want to have 4 doors (36" x 96" for example) in total, you would get 10 lengths (pcs) of 100" Single Rabbet 1 3/4" Jambs in a 4 9/16" width. Door Panels (=Slabs): Your door panels need to be 1 3/4" thick and usually they are smooth, flush, solid core hardboard doors. That is perfect door slab to be painted and to blend in with the smooth wall that will be eventually surrounding it. But if you want to use a 1 3/4" thick wood grain door (maybe veneered) you certainly can since only the thickness is critical. If you want a hollow core door you can do that as well and save some money that way. 3D Adjustable Hidden Hinges: Another critical component are the hinges. Hidden Door Hinges are widely available - even Amazon carries them now. However, not all of them are adjustable and you really want the 3 dimensional adjustability to make possible to align the door later in case your walls are not as level and plumb as you had hoped. So look for European made Hidden Hinges if possible. Brands like OTLAV IN230 or CEAM 1430 are good choices because they are nice and small but still hold the weight solid core door panels very well. If you are doing 36" x 96" doors, then 3 Hidden Hinges per door will be enough. Strike Plates: For strike plates you could use any kind of standard door strike but I do recommend to use magnetic ones since you are building a fairly high-end product in Frameless Doors. Again, many hardware stores online will carry such strike plates. Or you could also use a simple door catch in conjunction with a small door knob or door pull. Door Handles: Frameless Interior Doors can accommodate the same style of handles all other regular doors use or you can opt for "invisible' handles offered by some manufacturers. You will find those online when you search for "invisible door handles". Another alternate idea is to use a door knob or pull in conjunction with a door catch. This is most likely the cheapest option but still works well if you don't need to lock the door. If you want your door to be lockable I recommend to use a regular modern looking door handle. Step 2: Building your Frameless Doors The Concealed Door Frame (for Outswing Doors) For every door set you will need to cut a 45 degree miter angle at the top of the left and right jamb piece. The top piece of jamb will need miter angles on both sides. Left and right jambs will need to be the height of the door plus 2". In our example of 36" x 96" doors, that would be 98" for those 2 pieces. Based on 36" wide door, the smaller top piece will need to be 37 5/8" in total. In order to make the door frame invisible once installed, you will now need to attach a 90 degree PVC Drywall Angle (Trim-Tex makes it and it is called "tear-away L bead") to the underside of the door jamb along the whole length of the frame piece. The below diagram will make this clearer. You can either glue the angle to the frame or use a furniture stapler and staple it. Both options work equally well but stapling it is faster because there won't be any drying time needed. The Hidden Hinges Now you will need to router out the holes for the hidden hinges. We need 3 hinges on either the left or right jamb piece depending on your choice of swing direction. Once you decided on which jamb piece you need to work on, measure 8 1/8", 48 1/8" and 88 1/8" from the top of the frame towards the bottom. Those will be the centre lines of your 3 hidden hinges. The below picture will give you the hinge measurements so you can drill the holes to the correct dimensions. The diagram above that shows the door jamb in top view and where the hinges need to go (note: not to scale). The Door Panel (=Slab) (for Outswing Doors) The Door Panel (for Outswing Frameless Doors) needs to be drilled for the same 3 Hidden Hinges as the frame in their corresponding locations which are 8", 48" and 88" measured from the top of the door. Since the former dimensions are symmetrical over the height of the door panel, you can reverse the door panel to be either a left or right swing door. That means you do not have to pick the correct side. However, since a door panel always has one of its lengths mitred (the side where the handle is on), you never want to put the hinges on that side. Hinges always need to go on the 90 degree (perfectly square) side. I have included a diagram (note: not to scale) below showing the hinge locations. For hinge hole size refer to the same hinge dimensions given above - they will be exactly the same as on the concealed door frame. Handle, Lock and Strike Plate Since you have a variety of options for handle and strike plate types, we are only going to cover the standard North American handle and strike. When you buy a standard handle it will come with a strike plate in a set and you will also get instructions in the same package. It will tell you where to bore (drill) the door and how big the holes have to be. Oftentimes the package will come with a paper template to make it easier. But in general, a standard US door handle will require a 2 1/8" hole in the face of the door panel and a 1" hole in the door edge (the mitred edge) along the center line of the 2 1/8" hole. Some routering will also be required to have all the hardware sit flush with the door edge. The strike plate will sit on the frame and requires drilling and routering according to the instructions in your handle set package as well. Invisible door handles are available as mentioned earlier but will be more involved and need larger cut-outs in the door panel because they have more of a mortise lock design. That means they need a relatively deep square hole routered into the door face/edge. Step 3: Installing your Frameless Doors Your Rough Opening should be drywalled to the edge of the studs just the same way it is prepped for the installation of regular doors. The size of the opening needs to be 38" x 98" (for our 36" x 96" door size example that we have been working with so far).

The frame is currently in 3 pieces and you can now glue the mitred edges together using wood or construction glue. You can also screw the edges together but I prefer glue because screwing can move the frame pieces out of alignment if you are not careful. After the glue has dried and the frame is now in one piece, you will need to take the frame and set it into the rough opening. The drywall L-Angle that is attached to the frame will rest on the drywall on the side of the wall that the door swings to. That is also the side that will be the frameless door side. The opposite side cannot be flush with the wall. With Frameless Interior Doors only one side of the door can ever be in the plane of the wall. So you will have to choose if you want the Outside of the room or Inside of the room flush with the wall. Now that the frame is set in place, you need to shim it to make sure it is level and plumb. Then you will screw it into place on the handle side only - near top, middle and bottom of the frame. The wall will determine the plumbness to a certain extend because the frame rests with its L-Angle against the wall. Once you are happy with the location of the frame in the Rough Opening, you can now install the 3 Hidden Hinges. You should pre-drill the 6 locations where the hinge screws are located. Use at least 1 1/2" long screws to ensure that the screws penetrate into the wall studs. That will give you plenty of strength on the hinge side of the door where it is need. Solid Core door panels are heavy and you can use all the rigidity that you can get. The drywall L-Angle can be screwed into the drywall to avoid areas where it lifts off the drywall due to wall inconsistencies. You now have a choice of hanging the frameless door panel or finishing the wall-to-door interface. I prefer to hang the door quickly to double check that it swings correctly and does not bind anywhere. The I remove it and start with the next step: foaming the area between frame and studs. You can just buy low-expansion foam in your local hardware store and fill the gap mentioned above. Some foam will extrude out of the tight gap but do not remove it until the foam is dry. Then you can just cut the extruded portions off easily with an exacto-knife. This foam layer will give the door extra strength and keep vibrations to a minimum should the door ever be slammed closed in the future. The drywall will not have any mud on it at this point but now you need to start mudding the interface (where L-angle overlaps the drywall). You need to mud an approximately 12" wide strip around the perimeter of the door up to edge of the concealed door frame. Yes, the 5/8" exposed edge of the wooden door frame gets mudded as well. When done correctly you will have a smooth surface around the door perimeter and the concealed door frame will not be visible when you look at the wall. After everything has dried sufficiently, you can install the handle and strike plate and put the door panel back in. Lastly you will need to paint the door and wall - usually in the same colour to blend everything together and make the door panel disappear as much as possible. And voila, you have just build and installed an Outswing Frameless Interior Door.

0 Comments

Leave a Reply. |

AuthorJony Hubert, BSc. Archives

January 2025

Categories |

RSS Feed

RSS Feed